Value Stream Mapping Template: A Lean Guide for Process Improvement

Value stream mapping template and methodology for identifying waste and improving process flow. Step-by-step VSM creation, key metrics, and worked examples.

A value stream mapping template does not improve anything by itself. The value comes from the process of building the map -- walking the actual flow, timing each step, measuring the wait between steps, and confronting the gap between how work actually moves and how leadership thinks it moves. That gap, in our experience, averages 10x: processes that should take hours take days, and the vast majority of elapsed time is waiting, not working.

After applying value stream mapping across 50+ operational transformation engagements in manufacturing, software delivery, and shared services, we have found that the value-added ratio in most organizations falls between 1% and 5%. That means 95-99% of lead time is waste. The value stream map makes this visible in a way that no process document or workflow diagram can.

This guide covers the core components of a value stream map, walks through creating current-state and future-state maps, provides three worked examples, and compares VSM to related methodologies. For how value stream mapping fits into the broader strategic toolkit, see our Strategic Frameworks Guide.

What Is a Value Stream Mapping Template?#

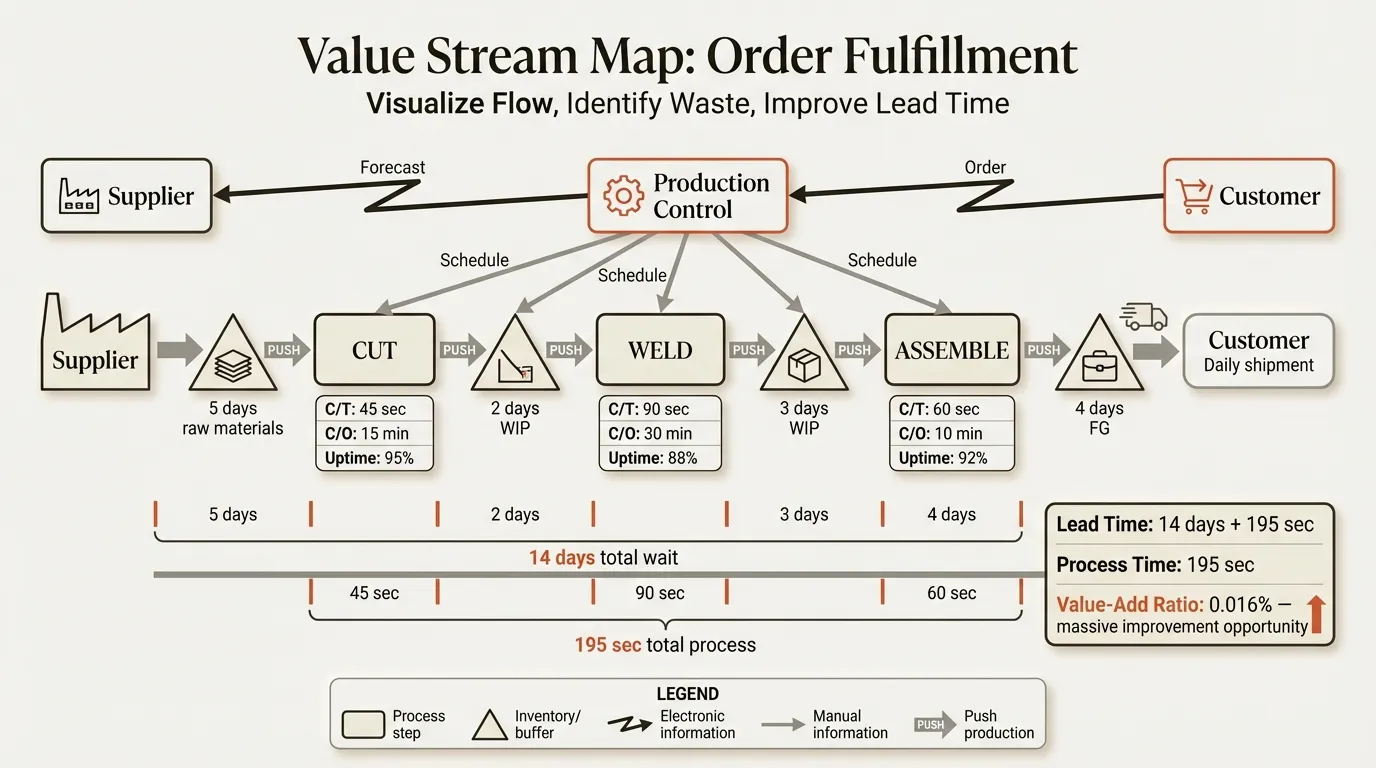

A value stream map is a visual representation of the entire flow of materials and information required to deliver a product or service -- from customer request to customer delivery. Developed as part of the Toyota Production System and formalized by Mike Rother and John Shook in Learning to See (1999), published by the Lean Enterprise Institute, VSM goes beyond documenting process steps. It quantifies the time, inventory, and information flows between steps to expose where value is created and where waste accumulates.

A value stream mapping template typically includes these components:

| Component | What It Captures | Why It Matters |

|---|---|---|

| Process boxes | Individual work steps with cycle time, changeover time, uptime | Shows where active work happens |

| Inventory triangles | WIP or queued items between steps | Reveals hidden buffers that inflate lead time |

| Data boxes | Cycle time, batch size, number of operators, defect rate | Provides the quantitative basis for improvement |

| Information flow arrows | How each step knows what to work on next | Exposes push vs. pull dynamics |

| Material flow arrows | Physical movement of products or work items | Shows transportation waste and handoff delays |

| Timeline | Value-added time vs. non-value-added time per step | Calculates the value-added ratio |

| Customer and supplier icons | Demand rate (takt time) and delivery cadence | Anchors the map to actual customer need |

The distinction between a value stream map and a simple process flowchart is the timeline at the bottom. That timeline splits elapsed time into value-added (active processing) and non-value-added (waiting, batching, transporting), and the ratio between those two numbers is the single most important diagnostic metric in Lean.

Key Metrics in a Value Stream Map#

Four metrics define the health of any value stream.

Lead time is the total elapsed time from the moment a customer places an order (or a request enters the system) to the moment the finished product or service is delivered. Lead time includes all waiting, batching, and processing time.

Cycle time is the time required to complete one unit of work at a single process step. If a machining step takes 45 seconds per part, that is the cycle time. Total cycle time across all steps is the sum of all individual cycle times.

Value-added ratio is the total cycle time divided by the total lead time, expressed as a percentage. A manufacturing process with 30 minutes of total cycle time and 14 days of lead time has a value-added ratio of 0.15%. This metric immediately communicates the scale of the improvement opportunity.

Takt time is the available production time divided by customer demand. If a factory operates 480 minutes per shift and customers order 240 units per day, takt time is 2 minutes per unit. Every process step must complete within takt time to meet demand without overproduction.

| Metric | Formula | Healthy Range | Red Flag |

|---|---|---|---|

| Lead time | Order to delivery (elapsed) | Industry-dependent | Growing over time |

| Cycle time | Processing time per unit per step | Below takt time | Exceeds takt at any step (bottleneck) |

| Value-added ratio | Total cycle time / lead time | 10-25% (optimized) | Below 5% |

| Takt time | Available time / customer demand | Stable | Varies widely across periods |

How to Create a Current State Value Stream Map#

Building a current state map is a data-collection exercise, not a design exercise. You are documenting what actually happens, not what should happen.

Step 1: Define the scope. Select one product family or service type. A value stream map that tries to cover every product variant becomes unreadable. Choose the family that represents the highest volume or the most strategic customer segment.

Step 2: Walk the process from end to start. Start at the shipping dock (or the point of customer delivery) and walk backward to the receiving dock (or the point where raw material or a request enters). Walking backward prevents you from following the "official" process and forces you to trace the actual flow.

Step 3: Record process data at each step. At each process box, capture cycle time, changeover time, batch size, number of operators, uptime percentage, and defect/rework rate. Use observed data, not estimates from managers. Time the process with a stopwatch. Count the inventory between steps.

Step 4: Map information flows. Draw how each process step receives its work instructions. Does a daily production schedule push work to each step independently? Or does downstream demand pull work from the upstream step? Most current state maps reveal a push system with disconnected scheduling.

Step 5: Build the timeline. Below the map, draw two rows: one for value-added time (cycle times) and one for non-value-added time (wait times between steps). Sum each row. Divide total cycle time by total lead time to get the value-added ratio.

Step 6: Identify waste. Mark every instance of the eight wastes: overproduction, waiting, transportation, overprocessing, inventory, motion, defects, and underutilized talent. The current state map makes these visible as inventory triangles, long wait times, and rework loops.

Continue reading: Agenda Slide PowerPoint · Flowchart in PowerPoint · Pitch Deck Guide

Free consulting slide templates

SWOT, competitive analysis, KPI dashboards, and more — ready-made PowerPoint templates built to consulting standards.

How to Design a Future State Value Stream Map#

The future state map answers one question: how should work flow to meet customer demand with the least waste?

Start with takt time. Calculate the pace at which the value stream must produce to meet customer demand. Every design decision in the future state must support this cadence.

Implement continuous flow where possible. Wherever two or more sequential steps can operate without batching or inventory buffers between them, combine them into a continuous flow cell. This eliminates the wait time between those steps entirely.

Install pull systems where flow is not possible. Where continuous flow is impractical (different cycle times, shared equipment, long changeovers), use a supermarket pull system: downstream processes withdraw what they need, and upstream processes replenish only what was consumed.

Identify the pacemaker process. This is the single point in the value stream that receives the customer schedule. Upstream of the pacemaker, use pull. Downstream of the pacemaker, use continuous flow. Only one point in the value stream should be scheduled directly.

Level the production mix. Instead of producing large batches of one product followed by large batches of another, level the mix to produce smaller quantities of each product more frequently. This reduces lead time and inventory.

Value Stream Mapping Template Example 1: Manufacturing Order Fulfillment#

Context: A mid-size manufacturer receives 400 orders per day for a product that moves through stamping, welding, assembly, and shipping.

Current state findings:

| Process Step | Cycle Time | Changeover | Batch Size | WIP Before Step |

|---|---|---|---|---|

| Stamping | 1 second | 60 min | 5,000 | 5 days of raw material |

| Welding | 38 seconds | 10 min | 100 | 4,600 units |

| Assembly | 46 seconds | 0 | 1 | 1,200 units |

| Shipping | 5 seconds | 0 | 400 | 2,700 units |

- Total lead time: 23.5 days

- Total cycle time: 90 seconds

- Value-added ratio: 0.003%

Future state design: Combine welding and assembly into a continuous flow cell (eliminating 4 days of WIP). Install a pull supermarket between stamping and the welding-assembly cell. Reduce stamping changeover from 60 minutes to under 10 minutes using SMED techniques, enabling smaller batches. Schedule only the welding-assembly cell (pacemaker). Target lead time: 4.5 days. Target value-added ratio: 0.015%.

Value Stream Mapping Template Example 2: Software Development Pipeline#

Context: A SaaS company's feature development process from product requirement to production deployment.

Current state findings:

| Process Step | Cycle Time | Wait Time Before Step | Batch Size |

|---|---|---|---|

| Requirements writing | 4 hours | 5 days (prioritization queue) | 1 feature |

| Design review | 2 hours | 3 days (waiting for reviewers) | 1 |

| Development | 16 hours | 2 days (sprint planning queue) | Sprint batch (10 features) |

| Code review | 1 hour | 1.5 days (reviewer availability) | 1 |

| QA testing | 3 hours | 4 days (QA backlog) | Release batch (20 features) |

| Deployment | 30 min | 7 days (release window) | Release batch |

- Total lead time: 42 days

- Total cycle time: 26.5 hours

- Value-added ratio: 3.9%

Future state design: Eliminate the sprint batching by moving to continuous flow for development (single-piece flow with WIP limits). Reduce code review wait time by implementing pair programming or automated review gates. Replace the biweekly release window with continuous deployment. Install a pull system for requirements: developers pull the next highest-priority item when capacity opens. Target lead time: 8 days. Target value-added ratio: 16%.

Value Stream Mapping Template Example 3: Customer Service Ticket Resolution#

Context: A B2B software company handling 200 support tickets per day across triage, investigation, resolution, and customer notification.

Current state findings:

| Process Step | Cycle Time | Wait Time Before Step | Batch Size |

|---|---|---|---|

| Triage | 5 min | 4 hours (email queue) | 1 ticket |

| Assignment | 2 min | 6 hours (manager reviews batch) | 20 tickets |

| Investigation | 25 min | 8 hours (agent backlog) | 1 |

| Escalation (30% of tickets) | 15 min | 24 hours (L2 queue) | 1 |

| Resolution | 10 min | 2 hours (waiting for info) | 1 |

| Customer notification | 3 min | 1 hour (batch send) | 50 tickets |

- Total lead time: 52 hours (non-escalated), 76 hours (escalated)

- Total cycle time: 45 min (non-escalated), 60 min (escalated)

- Value-added ratio: 1.4% (non-escalated)

Future state design: Replace batch assignment with automated routing based on ticket category and agent skill set (eliminates 6-hour wait). Enable agents to triage and investigate in a single step (continuous flow). Embed L2 specialists within the primary team to reduce escalation wait from 24 hours to 1 hour. Send customer notifications immediately upon resolution instead of batching. Target lead time: 6 hours (non-escalated), 10 hours (escalated).

Value Stream Mapping vs. Process Mapping vs. Value Chain Analysis#

These four methodologies serve different purposes. Choosing the wrong one leads to wasted effort.

| Methodology | Scope | Focus | Best For | Output |

|---|---|---|---|---|

| Value stream mapping | End-to-end flow for one product/service | Time, waste, flow efficiency | Operational improvement, Lean transformation | Current and future state maps with timeline |

| Process mapping | Single process or subprocess | Sequence of steps, decision points | Documenting workflows, training, compliance | Flowchart or BPMN diagram |

| Value chain analysis | Entire organization | Competitive advantage across activities | Strategic positioning, cost analysis | Value chain diagram with margin analysis |

| Swim lane diagram | Cross-functional process | Roles and handoffs between departments | Clarifying responsibilities, reducing handoff delays | Lanes with activities per role |

When to use value stream mapping: You have a specific product family or service with measurable flow, and the goal is reducing lead time, inventory, or waste. VSM requires walking the actual process and collecting time data.

When to use process mapping: You need to document how a single process works for training, compliance, or standardization. Process maps do not capture wait times between steps or inventory levels.

When to use value chain analysis: You are making strategic decisions about which activities to invest in, outsource, or restructure for competitive advantage. Value chain analysis operates at the business level, not the operational level. See our Value Chain Analysis Template for a detailed walkthrough.

When to use swim lane diagrams: You need to clarify who does what across departments for a specific process. Swim lanes are excellent for handoff analysis but do not capture time metrics.

Common Value Stream Mapping Mistakes#

After reviewing VSM exercises across dozens of engagements, we see the same mistakes repeatedly.

Mapping too large a scope. Teams try to map every product variant or the entire enterprise in a single map. The result is unreadable and unactionable. Map one product family at a time. If your map requires paper wider than a conference table, the scope is too large.

Using estimated data instead of observed data. Managers report cycle times based on what they believe happens. Actual observed times are almost always different -- sometimes by 2-3x. Walk the floor. Use a stopwatch. Count the inventory physically.

Ignoring information flows. Many teams draw only the material flow and skip the information arrows. But disconnected information flow is often the root cause of overproduction, batching, and excessive inventory. If every process step receives its own schedule from a central MRP system rather than a signal from the next downstream step, you have a push system with inherent overproduction. For techniques to trace root causes systematically, see our guide on Root Cause Analysis Examples.

Creating a current state map without a future state vision. A current state map that sits on a wall without a corresponding future state map is a diagnostic with no treatment plan. Always schedule the future state design session within one week of completing the current state map.

Confusing value stream mapping with value stream management. The map is a point-in-time snapshot. Sustaining improvement requires ongoing measurement of lead time, WIP, and value-added ratio. Build a value stream dashboard that tracks these metrics weekly. Connect your VSM findings to your broader project execution plan -- see our Project Plan Examples for structuring the improvement roadmap.

Presenting Value Stream Maps to Leadership#

A value stream map created on butcher paper during a kaizen event needs translation before it reaches an executive audience. Leadership does not need to see every data box and inventory triangle. They need three things: the current state summary (lead time, value-added ratio, major waste categories), the future state target (projected lead time, investment required), and the implementation timeline.

Structure the executive presentation as follows:

- One slide: Current state summary with the value-added ratio as the headline metric

- One slide: Top 3-5 waste categories ranked by impact on lead time

- One slide: Future state design with projected improvements

- One slide: Implementation roadmap with phases, owners, and milestones

For products that move through distinct lifecycle phases, connect your VSM improvements to the product's current stage -- our Product Lifecycle Management guide covers how operational priorities shift across introduction, growth, maturity, and decline.

Key Takeaways#

- A value stream mapping template is a diagnostic tool, not a solution. The value comes from collecting real data and designing a future state that eliminates waste.

- Walk the actual process from end to start. Use observed cycle times and physically count inventory -- never rely on estimates.

- The value-added ratio (typically 1-5% in unoptimized processes) is the single most important metric. It quantifies the improvement opportunity in terms leadership understands.

- Map one product family or service type at a time. Overly broad scope produces maps that are unreadable and unactionable.

- Always pair a current state map with a future state design. Current state alone is diagnosis without treatment.

- Choose the right methodology for the problem: VSM for operational flow improvement, process mapping for documenting workflows, value chain analysis for strategic positioning, and swim lanes for clarifying cross-functional responsibilities.

Build consulting slides in seconds

Describe what you need. AI generates structured, polished slides — charts and visuals included.

Try Free